Supply chain mapping: how to get started

Supply chain mapping is an essential part of sourcing responsibly and sustainably. Learn what this is and how to get started with our helpful overview.

What is supply chain mapping?

Mapping your supply chain means gathering information about the suppliers, worksites, operations and workers in your supply chain to create a detailed global map. This information can be held in a single data platform for ease and to enable integrated analysis on working conditions, management practices and supply chain risks.

Building your supply chain map isn’t just a one-off exercise – it’s an ongoing activity to build and maintain a detailed picture of your supply network. This picture evolves as you get more information, and as your supplier base and supply chain change.

Why is it important?

Mapping your supply chain helps your business learn more about how their products or services are produced, where and by whom. It’s the foundation for building a risk management, supply chain due diligence or sustainable sourcing programme.

Supply chain mapping brings numerous benefits to a business that go far beyond simply providing visibility and meeting legal requirements.

The benefits of mapping your supply chain

- Create supply chain transparency and visibility. Investors, lawmakers and consumers expect a business to know how and where their products are made.

- Identify, understand and respond to inherent risks in your supply chain, to protect your operations and reputation against these. For example, some countries have higher rates of exploitative practices like child labour, while in others there are high demands on environmental resources. Knowing where suppliers are located helps to understand the most relevant and biggest risks where they are, helping your business respond to these risks, build resilience and drive more sustainable practices in your supply chain.

- Know where to take action to address issues and protect workers. Having more information about suppliers and workers empowers your business to understand the human rights and environmental impacts that purchasing decisions may have throughout your supply chain.

- Comply with supply chain legislation. Modern Slavery Acts and other laws require companies to demonstrate how they address modern slavery, including within their supply chains. To comply with these, companies must know who their suppliers are, the risks of modern slavery and what actions are being taken to prevent and remediate this if it’s identified.

- Report on ESG criteria and attract investors. ESG data is increasingly interesting to investors looking to understand the potential environmental and social risks of an investment prospect. Supply chain mapping is a core part of a comprehensive due diligence programme, something that reassures investors that your business understands their supply chain and has accurate visibility of the sustainability risks within it.

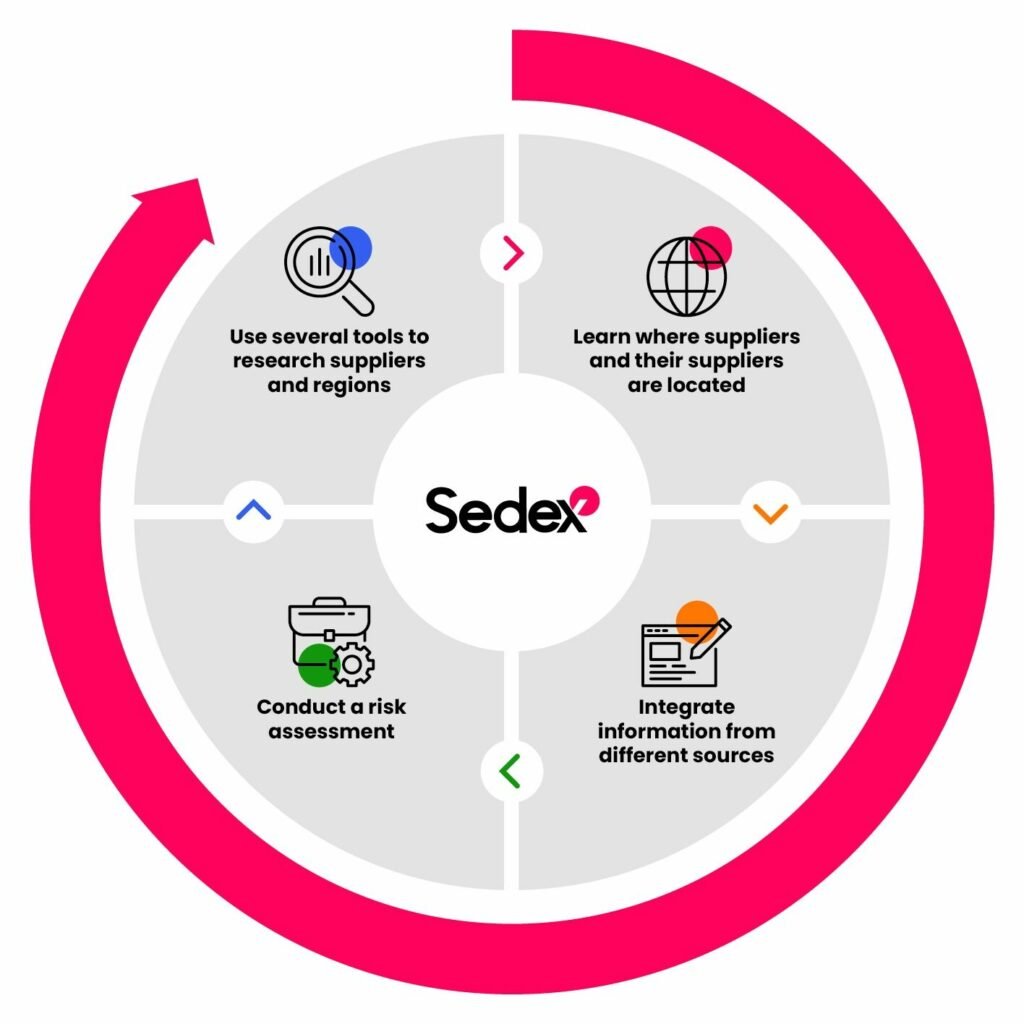

How to map your supply chain

There are four key steps in the process to map a supply chain.

1. Learn where your suppliers and their suppliers are located by working with your procurement teams, starting with existing supplier lists.

2. Integrate supplier information from different sources using a spreadsheet or data platform. Supply chains can change rapidly; a system for managing supplier data helps you to keep information current and enables comprehensive data analysis.

3. Conduct an initial risk assessment to help you prioritise where to focus your next steps, such as closer investigation or taking action to address sustainability issues.

4. Research your suppliers through additional tools and sources, e.g. news articles. Collect information about what is happening at supplier worksites, and research the inherent risks associated with the countries and sectors they operate in.

Other examples of supply chain mapping tasks include engaging with your direct suppliers to gather information on their suppliers, and using publicly available import/export data to see where certain materials may originate from.

Continue the mapping process as your supply chain evolves — the more information you have, the more valuable insights you’ll gain. Once you have a good idea of where top-tier suppliers’ sites are, look at the businesses that supply them, i.e. their suppliers. If you use several wholesale agents, you may want to start this earlier in your process.

Tips for getting started

- Identify who will be responsible for gathering information about suppliers and storing this in one place.

- Speak to stakeholders across business departments, look at suppliers’ invoices and check the addresses on their websites.

- Use tools like the Sedex Self-Assessment Questionnaire (SAQ) for suppliers and pre-screening risk tools to gather data and risk insights.

Get help with mapping your supply chain

At Sedex, we can help your business get started with our supply chain mapping tools and sustainability data platform. We help more than 75,000 businesses in 180 countries to drive sustainable practices through their operations and supply chains, including Reckitt, Molson Coors, Japan Airlines and Unilever.

Gather information on suppliers

This includes where they are located, the activities occurring at different sites and the people working at them. Our tools capture data about suppliers’ and businesses’ own sites, which feeds into supply chain sustainability analysis and risk assessment.

Supplier engagement and onboarding

The Sedex platform holds all this information in one place to build an interactive map with reporting. Sedex Supplier members can also share their data with multiple customers at once to save time and avoid duplicating their efforts.

How could we help your business?

Case study: DuPont Nutrition

DuPont Nutrition and Biosciences work with Sedex to drive efficiency, improve transparency and nurture business relationships in their supply chain.